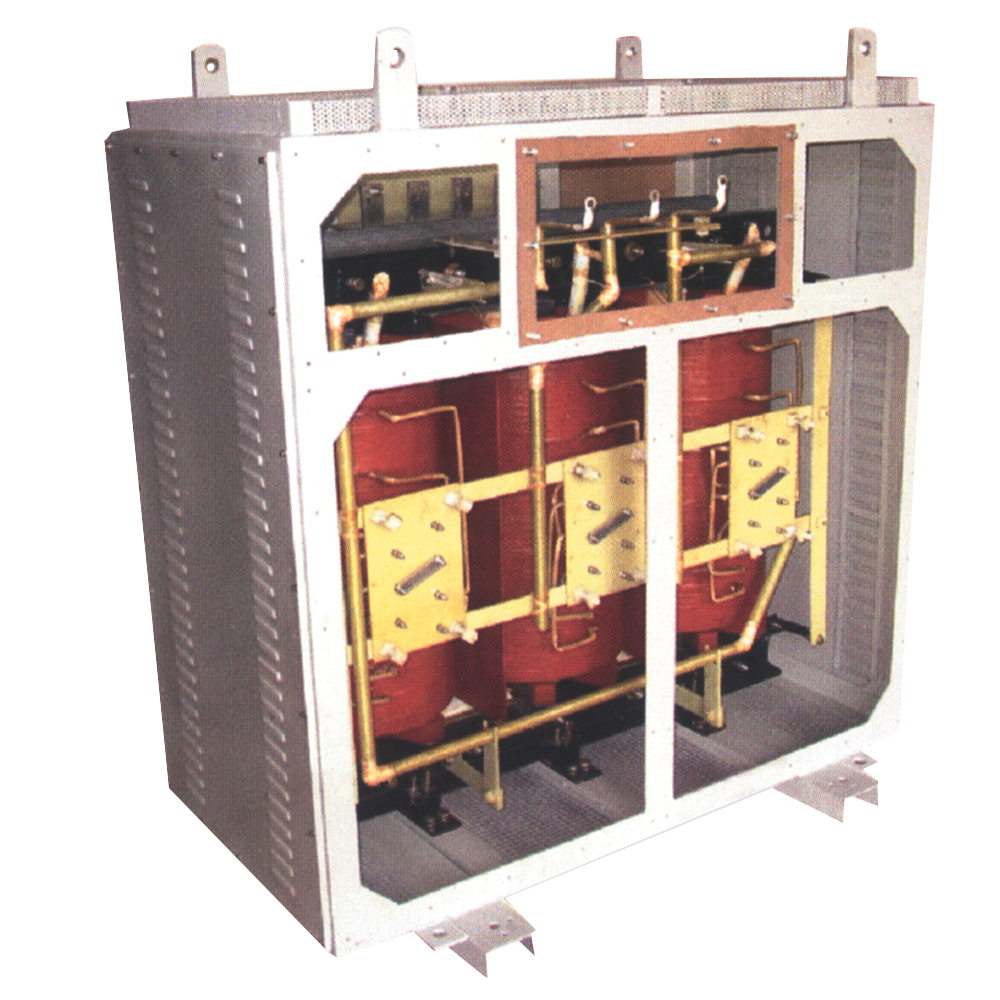

Resin cast Transformer

Our cast resin transformers are designed so well that they are

able to withstand extreme temperature and harsh weather conditions.

The best part about our cast resin transformers is that they are easy to install and maintain.We make sure that

our transformers are free from any type of magnetic loss, leakages or spikes. We make available in transformer

products in different grades and technical specifications as required by our global clientele.

Main features :

-

Magnetic circuit with CRGO lamination M3 to M5, MOH and ZDKH types

-

Electric circuit: copper 99.9% pure electric grade, foil for LV and strip for HV, duly casted with resin under vacuum

-

Dielectric circuits: Nomex glass fiber components along with resin casted components

-

Thermal Circuit: natural cooling through effective axial and radial ducts and air vent between LV to HV and LV to Core

Specific features:

-

Design conforms to relevant standards IEC 76, IEC 726, IS 11171, IS 2026 and as per any other international standards

-

Designed to withstand short circuit forces, thermal stresses and electrical impulses. Low partial discharge

-

Low load power losses and low noise

-

Fire retardant, compact and best suited for indoor installations

-

Installation can be very close to load center thereby LT cable cost saving

-

Advanced manufacturing techniques to ensure.mst effectiveness

-

Reliable, user friendly, easy to install and occupies less space

Specification:

-

Cast resin dry type transformer 11kv/433V, 3phase, 50 Hz.

-

Off circuit tap links +/-5% in steps of 2.5%.

-

Class F and H insulation.

-

HV Delta connected, LV Star connected with Dyn 11 vector group.

-

Installation can be very close to load center thereby LT cable cost saving

-

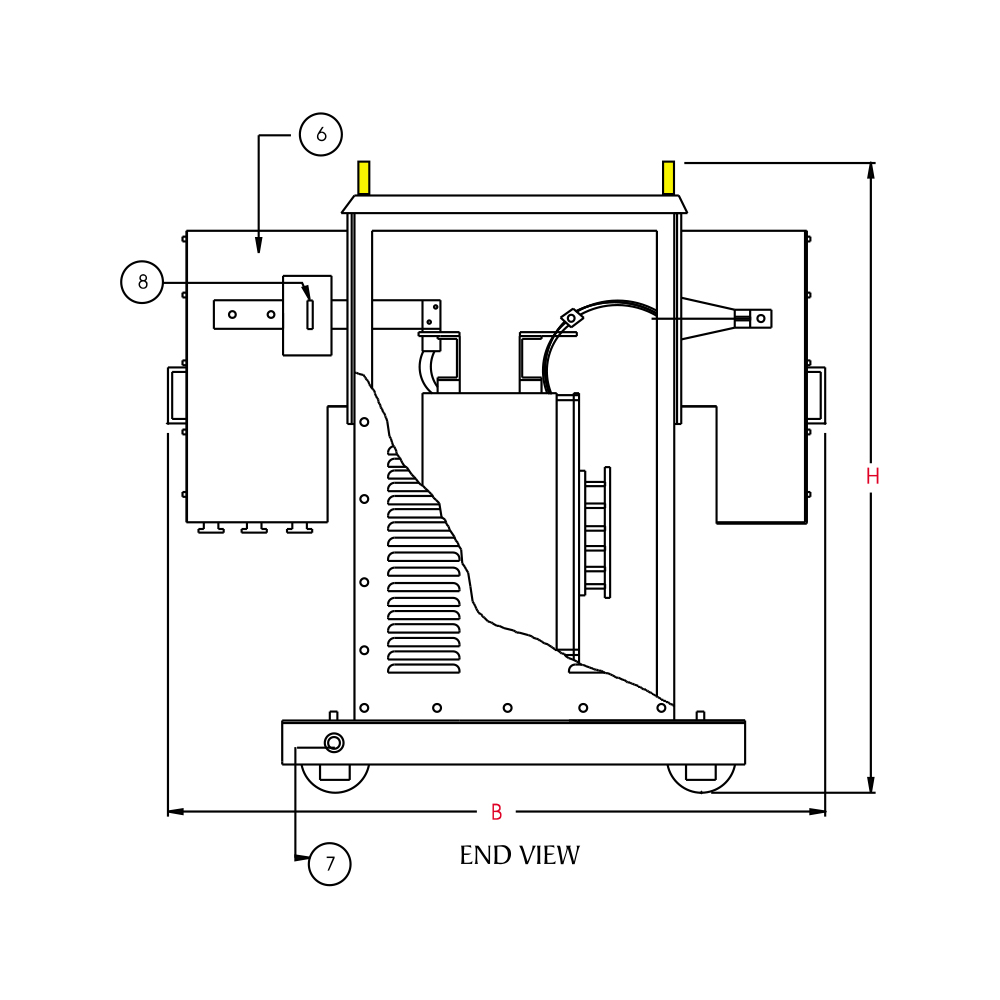

Natural air cooling and forced air cooling.

-

Duty cycle – continuous.

-

Winding- copper duly resin casted.

-

Enclosure - IP 23 to IP 33 and as per customer specifications.

-

Cable boxes on HV and LV.

-

Painting shades as per IS and IEC standards.

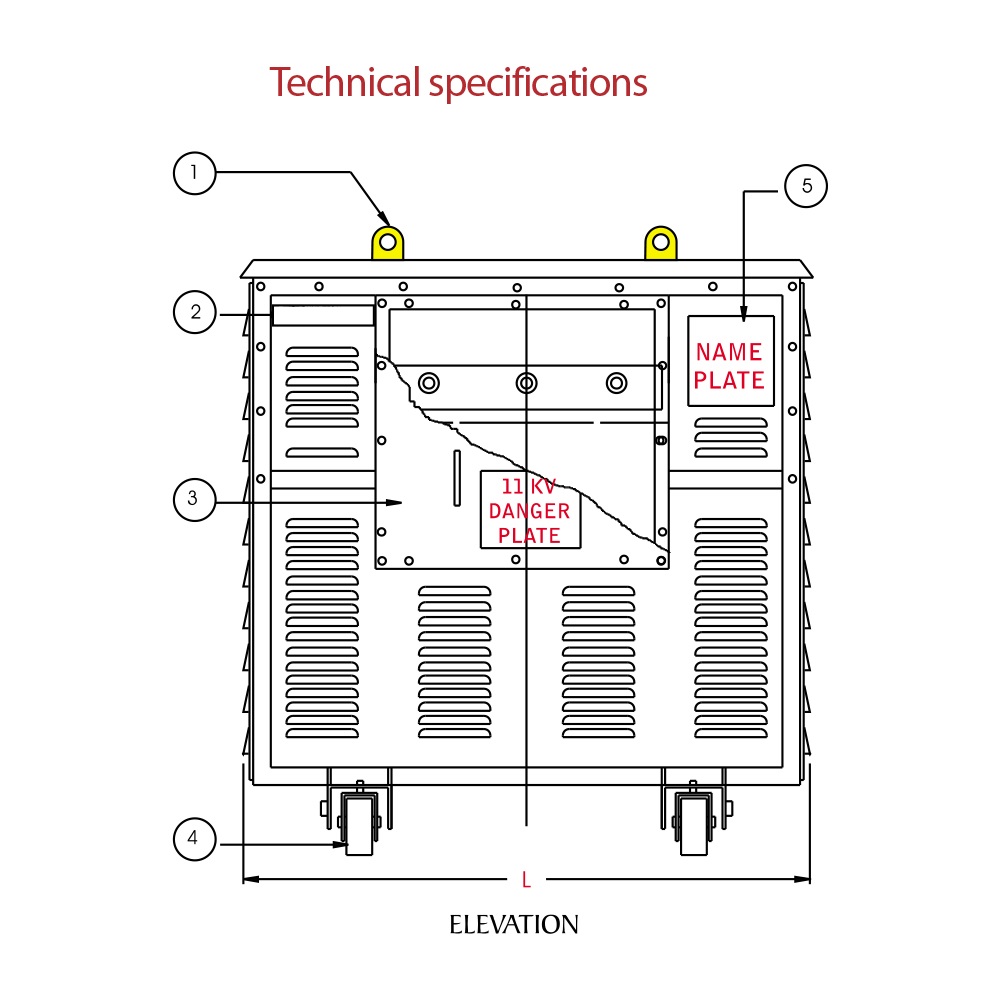

Standard fittings:

-

Rating and diagram plate

-

Earthing terminals-2

-

Off-circuit tap links

-

Enclosure-IP 21 For Indoor/IP 43 for Outdoor application

-

Jacking lugs

Optional accessories:

-

PT-100 sensors in each coil

-

Winding temperature scanner with alarm and trip coil

Inspection and testing:

-

Incoming material inspection at vendors place

-

Stage inspections at end of each process

-

Identification and traceability

Final routine tests as per IS and IEC standards conducted as follows:

-

Voltage ratio

-

Winding resistance

-

Impedance voltage

-

No load current with losses and load losses

-

Separate source voltage withstand test

-

Insulation measurement

-

Induced over voltage test

-

Noise level measurement